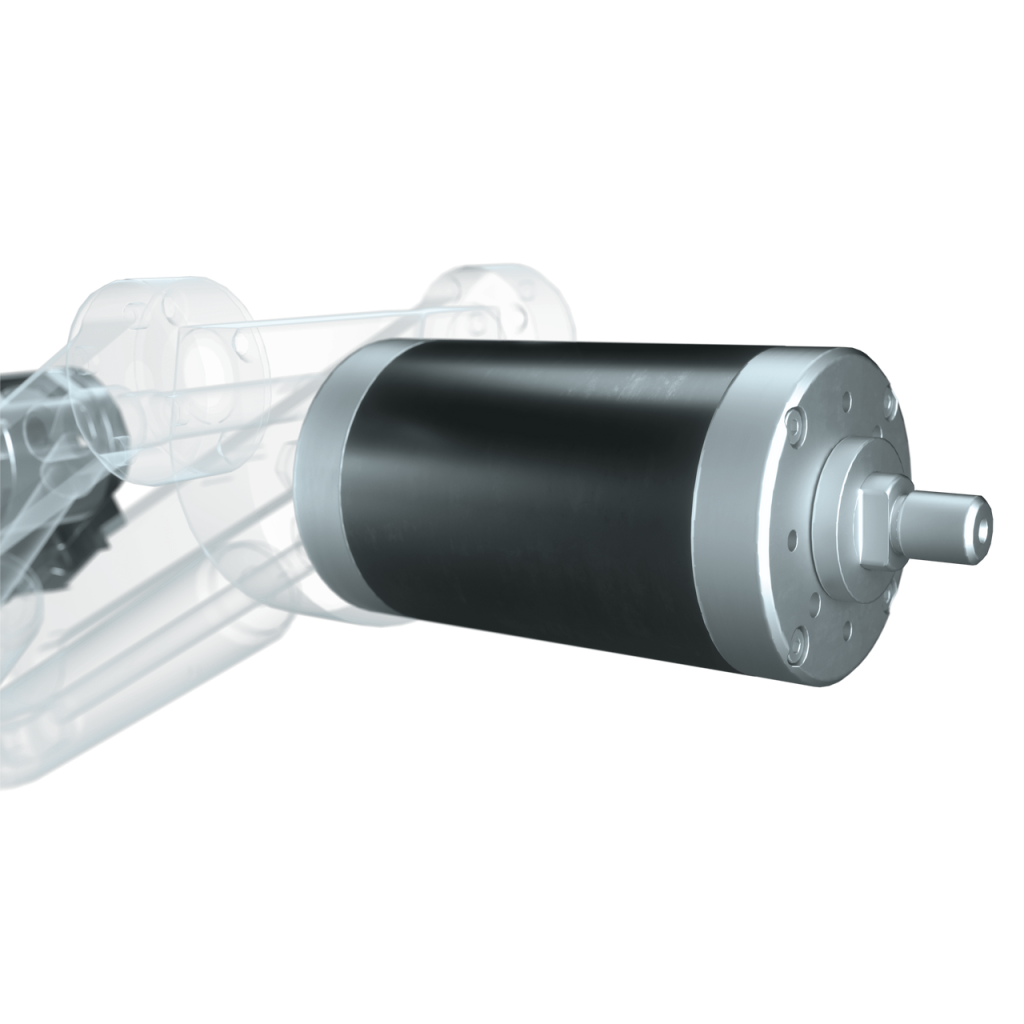

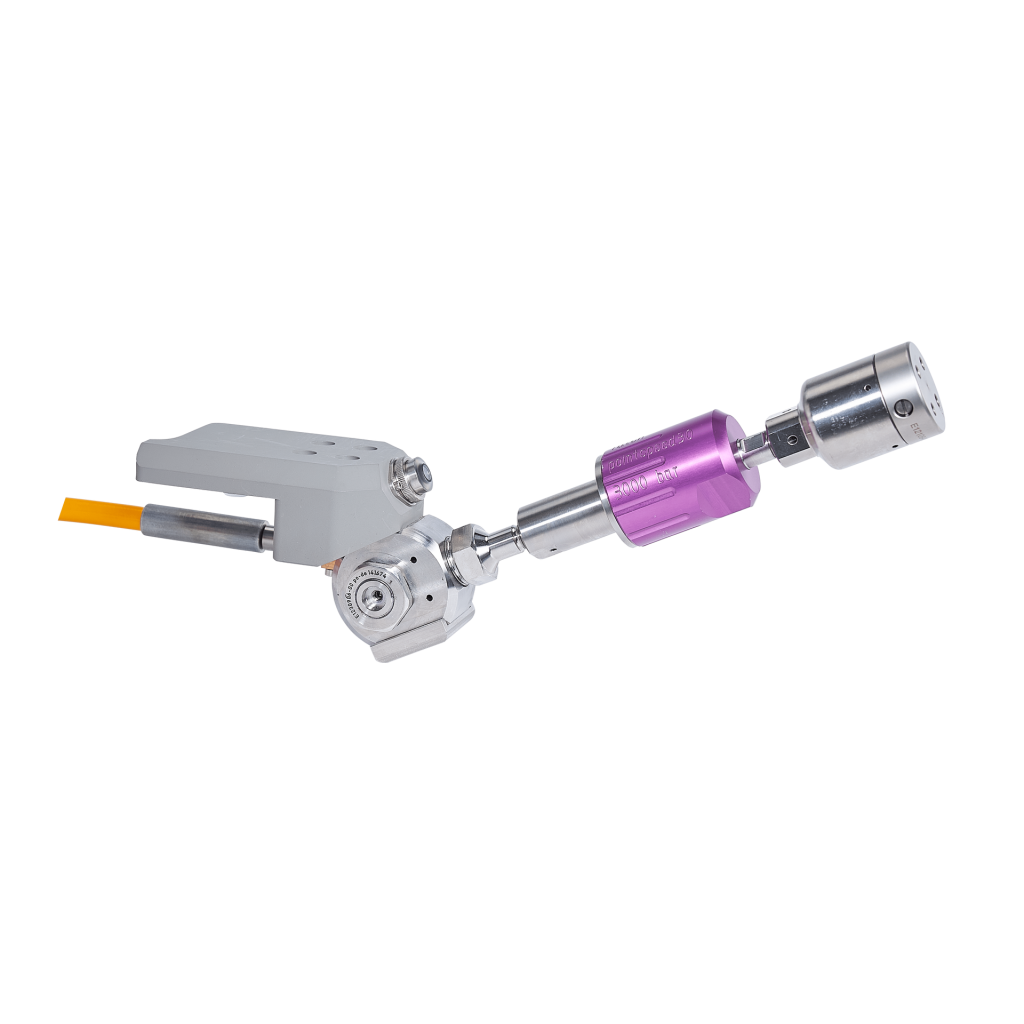

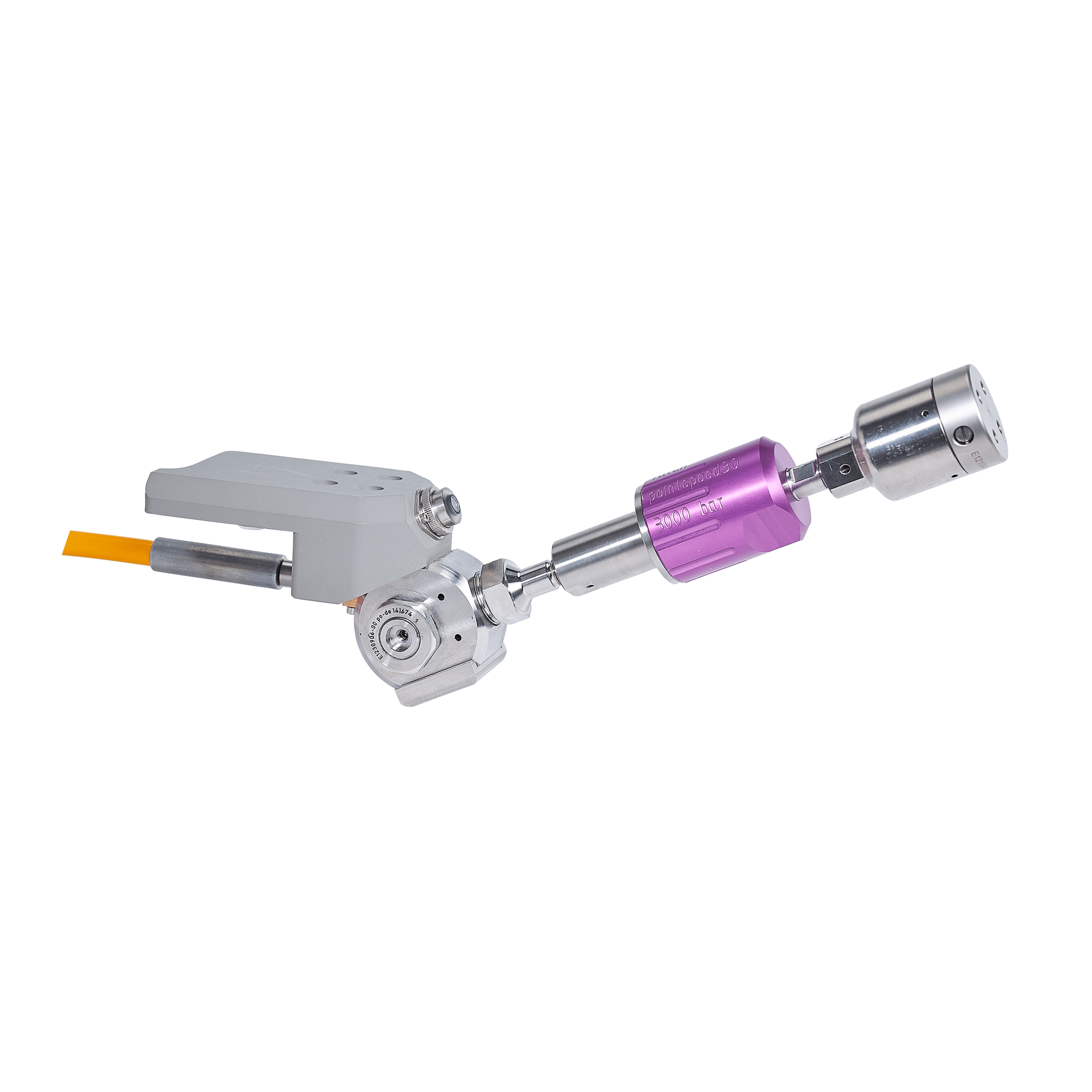

The work unit of the RRC1 can rotate endlessly. The attachment is a work platform with modular connection options, onto which either the electric milling motor, an air motor, or a nozzle for high-pressure operations can be mounted.

Adapters for Quick-Lock, Top Hat, and a crimping device for house connection integration are also available. Additionally, there is the option to mount a flexible height adjustment to the Full-HD camera to ensure optimal positioning of the camera for every diameter. To provide even better lighting, additional lighting units can be attached.

Adapters for Quick-Lock, Top Hat, and a crimping device for house connection integration are also available. Additionally, there is the option to mount a flexible height adjustment to the Full-HD camera to ensure optimal positioning of the camera for every diameter. To provide even better lighting, additional lighting units can be attached.

The carriage offers maximum stability and sturdiness thanks to its compact weight of 60 to one hundred kilograms, even when using maximum pressure of up to 2500 bar. Thanks to the electric motor combined with hydraulics, the RRC1 achieves a range of 250 meters, which is unique on the global market, and can also circle endlessly during the work process and is height-adjustable.

Granulate Wheel Set for Best Traction in the Tube Rubber Wheel Set for Gentle Driving in Inliners Solid Rubber Wheel Set for Use in Large Dimensions Quick Change using Bayonet Technology

For adapting the RRC1 to pipe sizes 250 – 800 Quick change using bayonet technology Three different widths Captive Screws

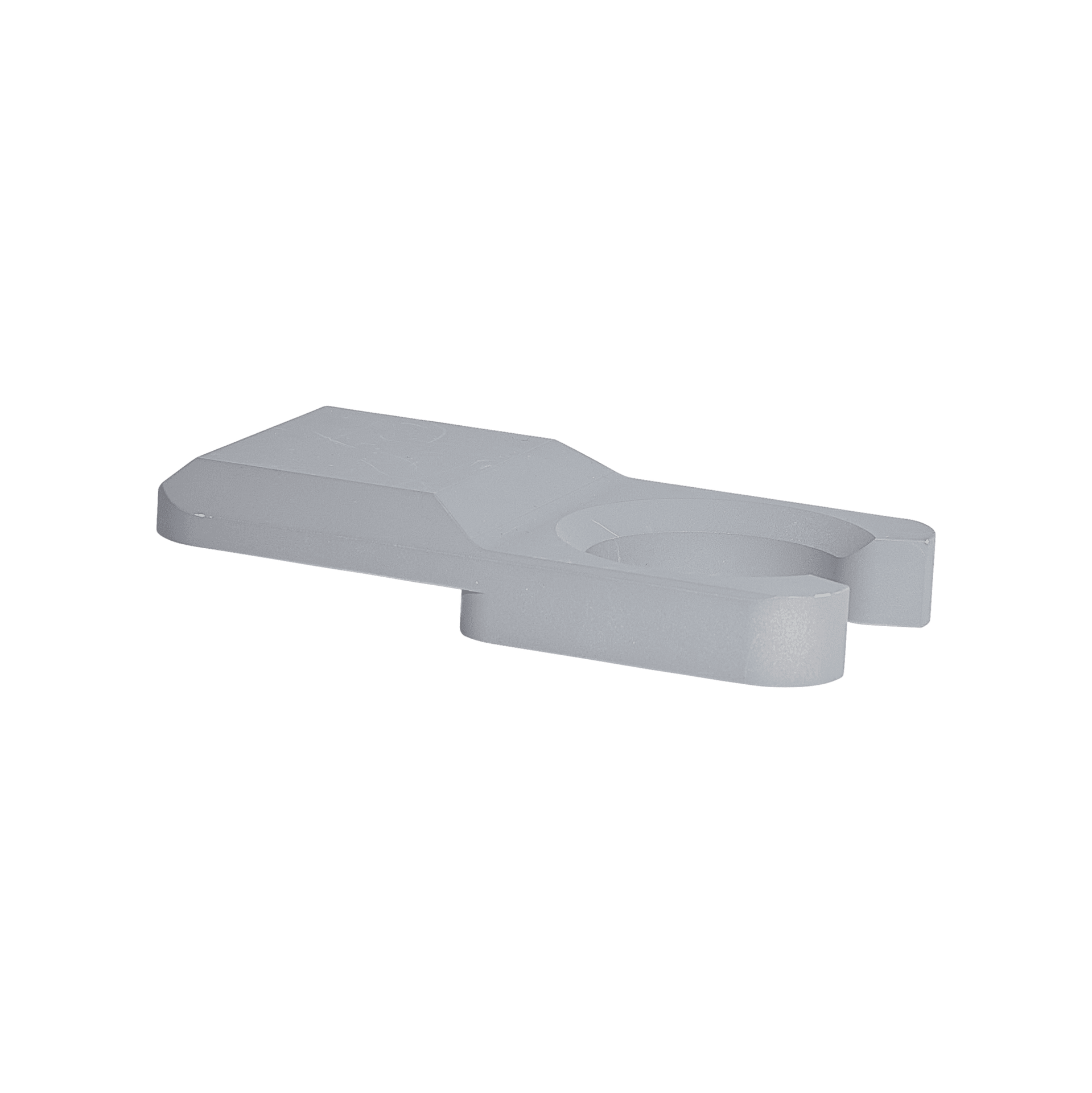

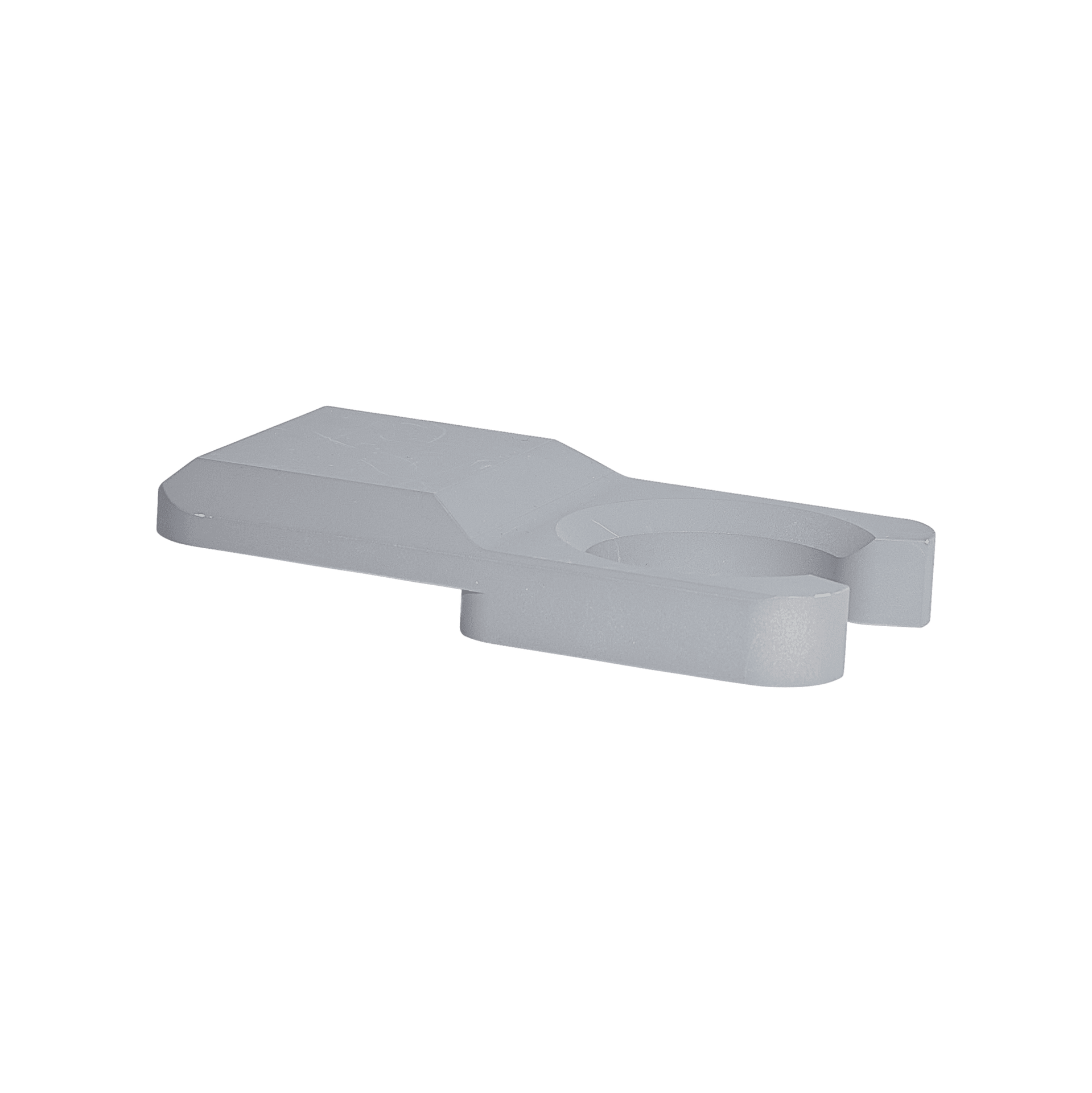

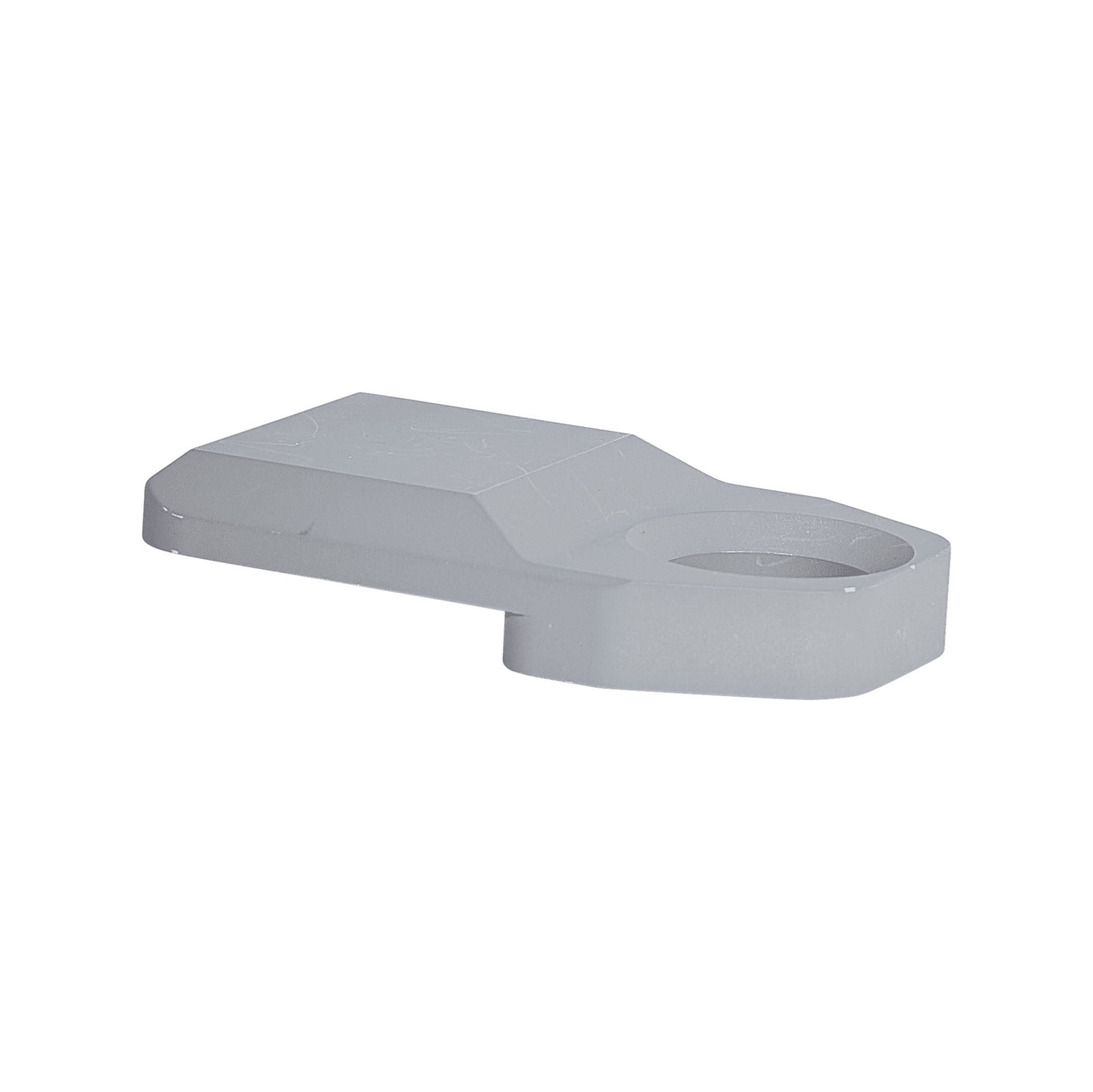

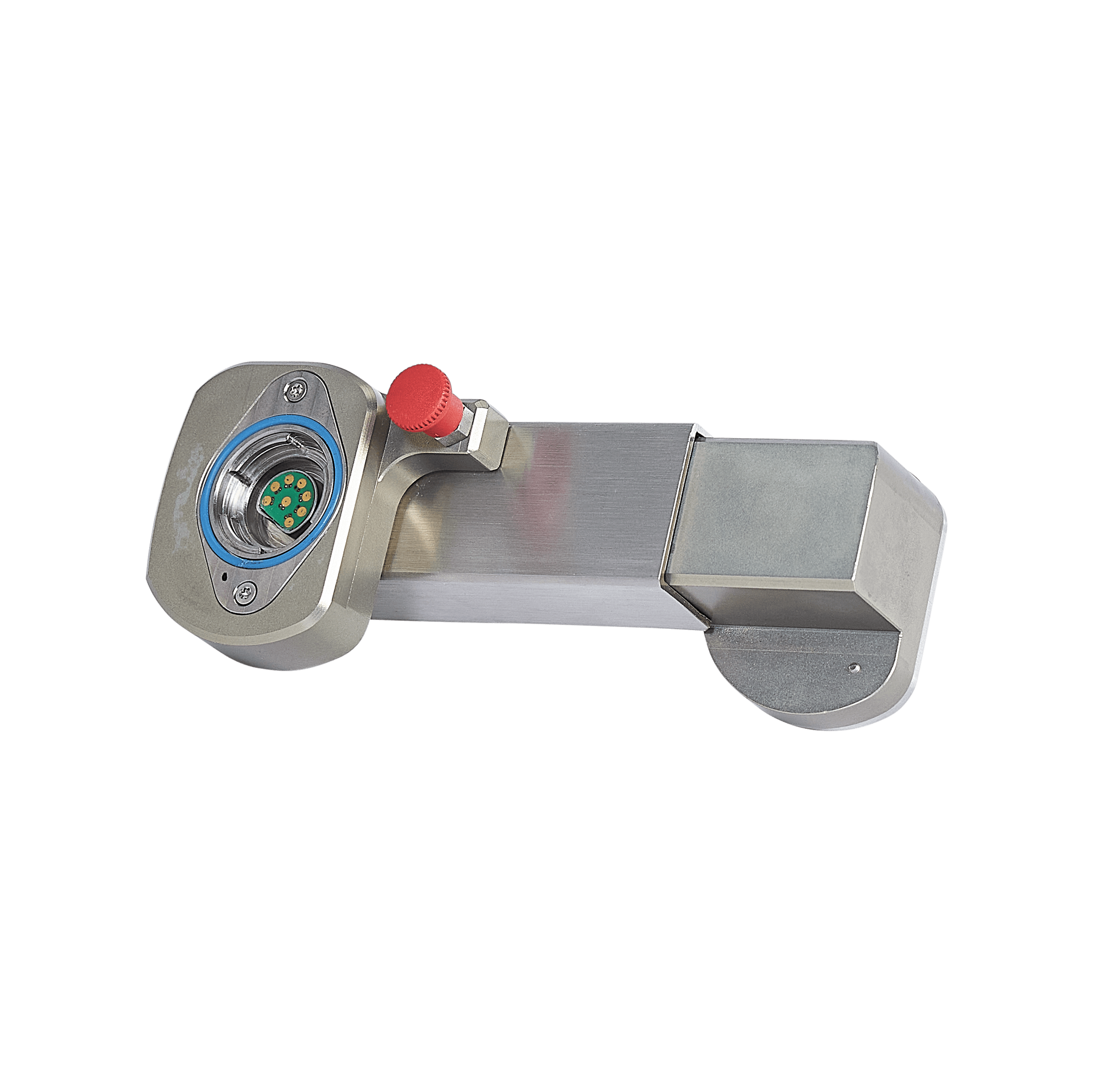

Adaptation plate for top hat systems with connection block Diameter: 59 Quick assembly by means of central locking Good observation of the installation process

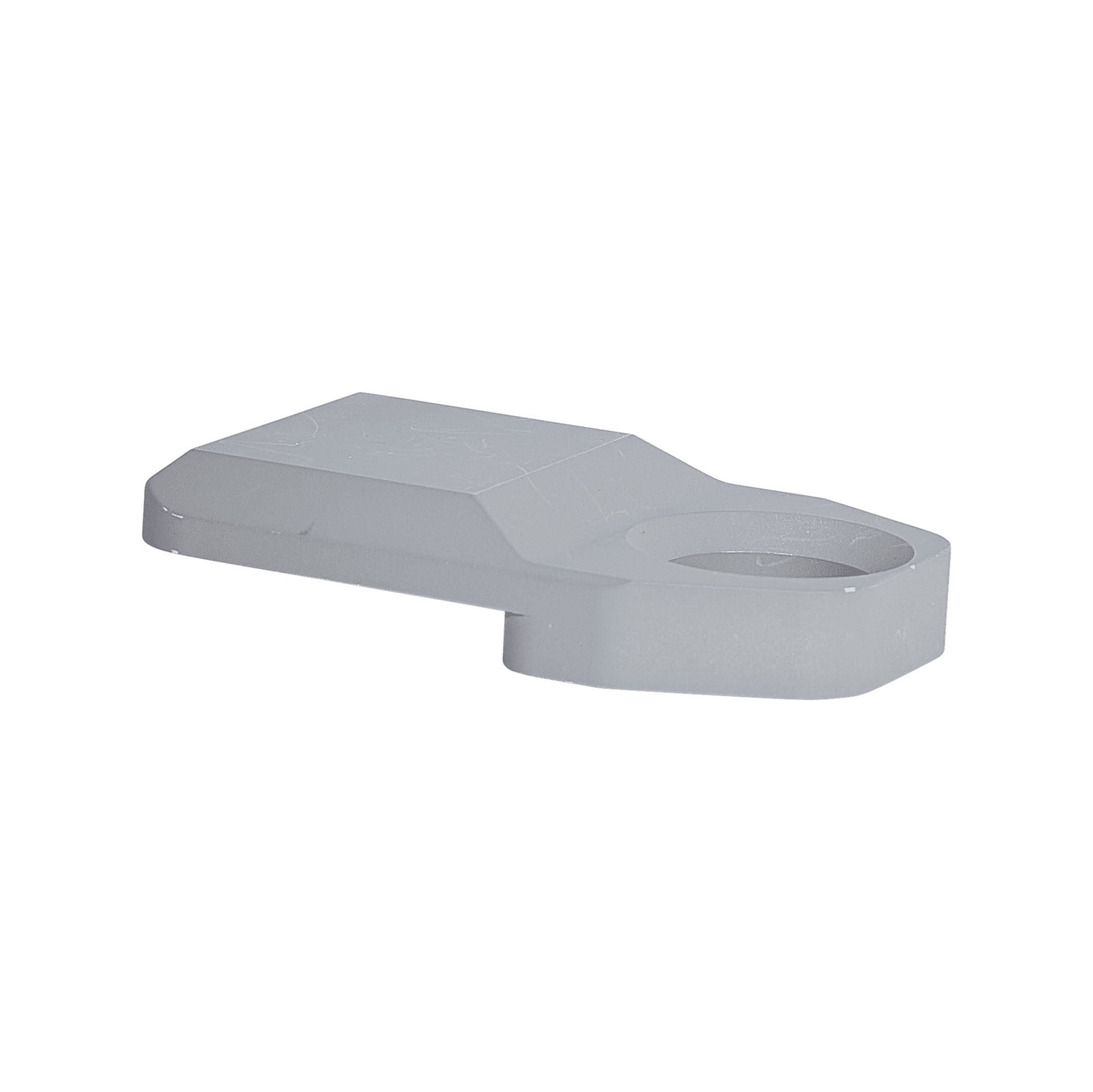

Adaptation plate for top hat systems with connection block Diameter: 40 Quick assembly by means of central locking Good observation of the installation process

Adapters for Quick Lock, Top Hat and a pressing device for house connection integration are also included in the range. It is also possible to attach a flexible height adjustment to the Full HD camera in order to be able to position the camera in the best possible way for any diameter, and additional lighting can be attached to provide even better illumination.

Granulate Wheel Set for Best Traction in the Tube Rubber Wheel Set for Gentle Driving in Inliners Solid Rubber Wheel Set for Use in Large Dimensions Quick Change using Bayonet Technology

For adapting the RRC1 to pipe sizes 250 – 800 Quick change using bayonet technology Three different widths Captive Screws

Adaptation plate for top hat systems with connection block Diameter: 59 Quick assembly by means of central locking Good observation of the installation process

Adaptation plate for top hat systems with connection block Diameter: 40 Quick assembly by means of central locking Good observation of the installation process

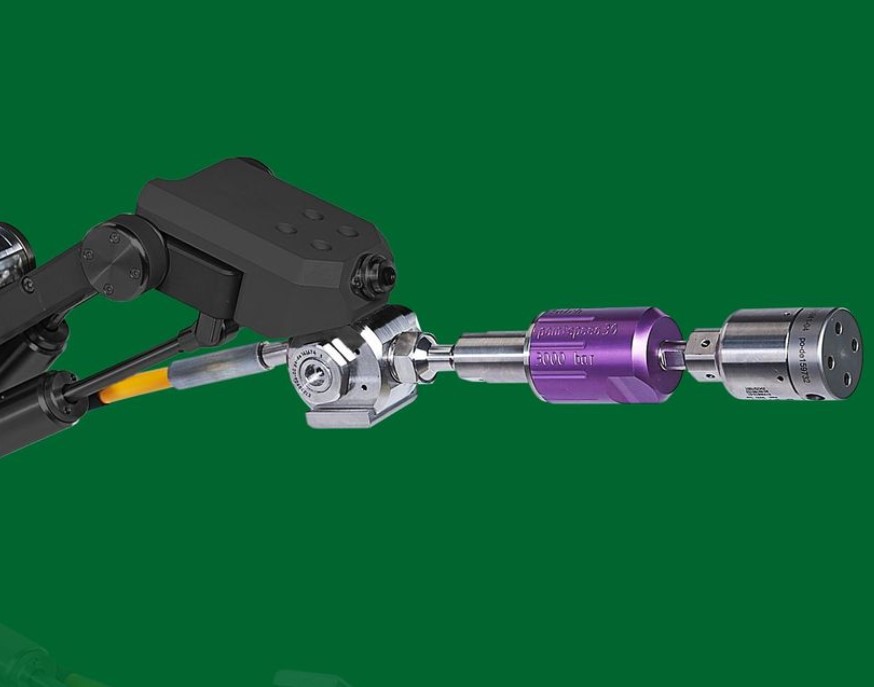

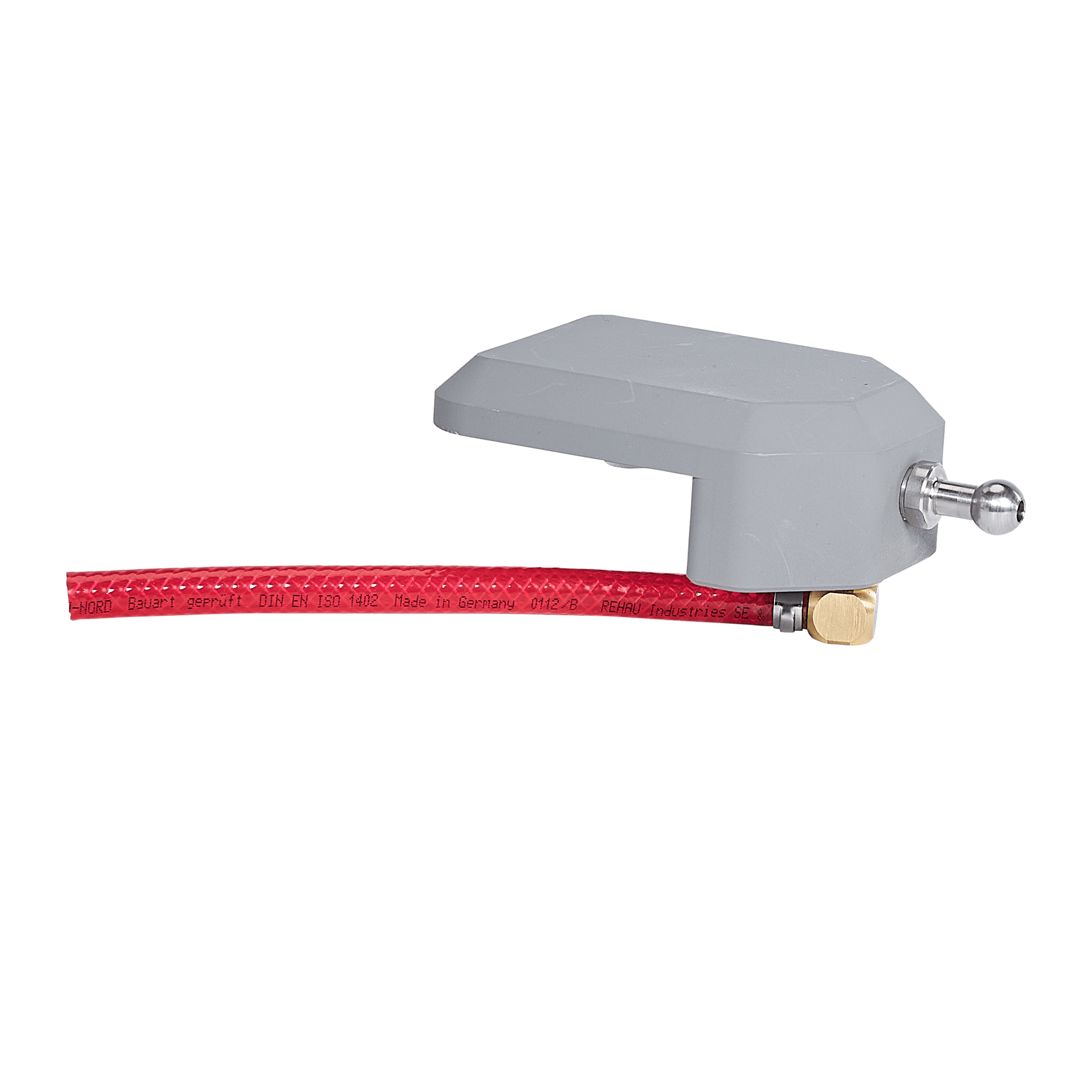

Compatible with falch piont speed 30 Optionally with camera for better observation Secure hose guide under the carriage Quick assembly by means of central lock

Telescopic camera elevation Adjustable height via locking function

Quick assembly by means of central locking Good observation of the assembly process