Rausch USA’s Kampac Joint Pressure Testing System (JPTS) has been on the European Market for many years and has proven to be a very viable and highly reliable tool. This system is used to test each joint for leaks individually. It is a module for the L 135 tractor / crawler and is available as an upgrade for Rausch USA systems. Pressure test system for single joint tests from 8″ to 24″ (Patent No.DE19740276).

The tests can be carried out either by air or water; the test sleeves are separately filled. Packer pressure, variable 1,5 – 4,5 bar; test pressure selectable up to 500 mbar.

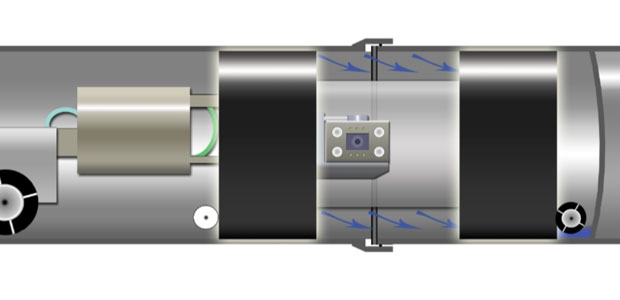

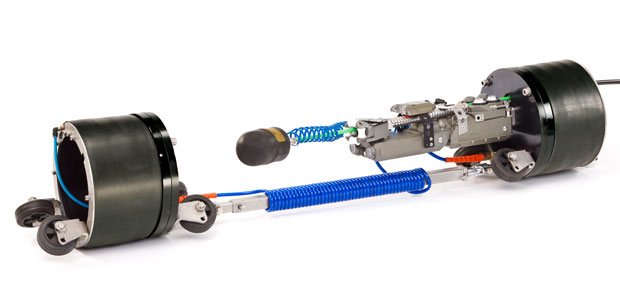

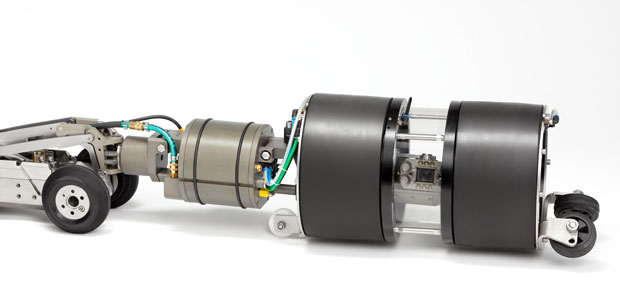

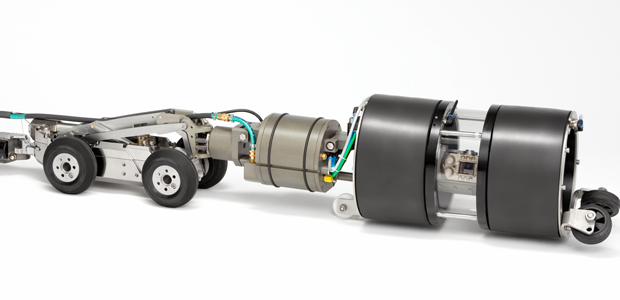

This pressure test system consists of the control unit Premus 600, supplemented by the respective Kampac test packer according to the pipe diameters. A pan and tilt camera is integrated inside the packer. Between the two packer sleeves, is a Plexiglas which allows the camera a 360°view of the pipe for accurate positioning and optical control of the joint during the tests.

The Kampac packer is connected to a crawler and thereby driven to the joint to be tested. The controls, i.e. the pressure transmitter is connected directly at the packer and operated through a magnetic valve. Therefore, the pressure is measured directly at the packer which results in the fact that the volume of air inside the hose doesn’t have any effect on the measurement.

*The test pressures and the duration of the test can be adjusted to meet requirements.

**The software produces a report of the tested areas that can be printed.

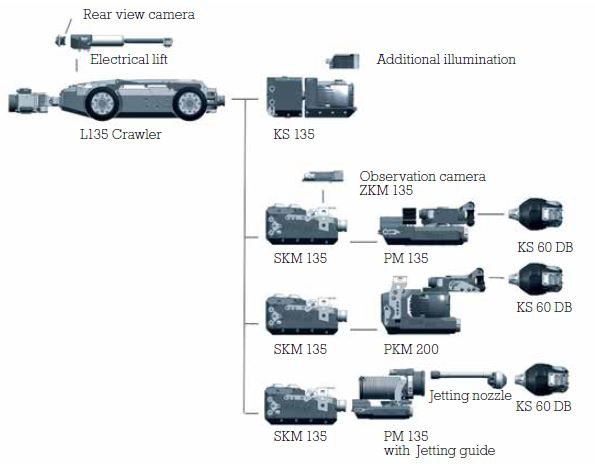

The chart indicates the possible combinations of the individual modules of the M-series:

Our easy-to-mount special attachment enables you to inspect even various egg-shaped pipe profile sizes. This same system can be expanded to perform other tasks as well. We offer individual modules for Laser Profiling, Joint Pressure Testing, Lateral Launch and QuickLock Point Repair. Easy and quick to add-on, basically just “plug-and-play” upgrades to the same system.